Helium recovery and purification is an emerging market in North America due to the critical shortages resulting from high demand across numerous markets. Producers are realizing the profitability of wells containing fractional amounts of Helium.

At ARJAE Design Solutions we have the answer for all your helium recovery and purification needs. Our patent pending design offers up to 99.9% recovery and 99.999% purity.

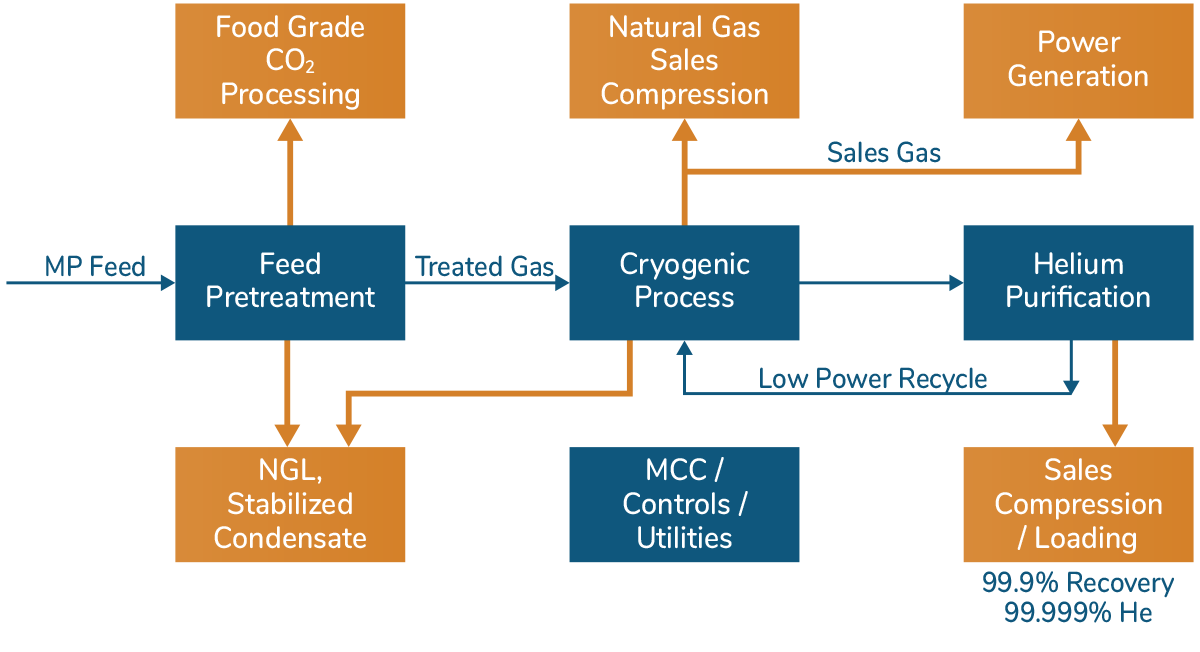

Flow Diagram

Revenue Streams

- Helium – high recovery, high purity

- CO2 – high recovery, purification, and liquefaction for food/beverage-grade CO2

- Nitrogen – high recovery used as effluent stream in the process, however can be recovered if required

- Hydrocarbon – cryogenic process offers recovery of hydrocarbons that can be processed to sales quality fuel gas, NGL and Condensate products. Typical recoveries provide fuel gas for power generation in excess of plant requirements, thereby allowing for additional supply to other value streams (sales gas to pipeline, power generation back to grid, bitcoin miners, etc.).

ARJAE’s Proprietary Design

- Cryogenic process recovers 99.9%+ of the available helium in the feed stream.

- ARJAE’s patent pending process is completed without the use of expensive turbomachinery or compression, resulting in significantly lower overall plant power consumption.

- We can recover additional value streams to provide increased revenue at relatively low additional capital cost.

- In-house engineering, design and fabrication.

- Modular design concept to reduce site installation costs.

- Pre-commissioned modules to start producing faster.

- To ensure compliance with increasingly stringent environmental regulations, ARJAE’s patented process recovers the GHG which reduces the risk of imposed shutdowns.

- Does not require continuous replacement of components such as membranes.

- All components are readily available from local vendors in the event of repair or replacement. No special membranes or patented rotary valves required!