ARJAE Design Solutions Ltd. has vast engineering experience in oil and gas. Our expertise is designing and managing projects from preparation of stock equipment to delivery of high specification turnkey facilities. These include complex multi-discipline projects such as turnkey oil and gas facilities, custom-engineered modular packages for client proprietary systems, R & D to commercialization and standard oil treating and fired equipment packages.

We design for the future through engineering excellence, make quality and efficiency priorities and strive to meet or exceed project expectations, regulatory and code requirements, and project specifications while meeting project timelines and budgets.

In this ever-changing world, ARJAE has taken steps to secure work and personnel experienced in the area of renewable energy, including renewable diesel, renewable natural gas and synthetic gas (syngas) production.

Project Management

- ARJAE Design Solutions offers an experienced team of professionals that will effectively manage your project from the concept/feasibility phase through to installation, commissioning, and start-up.

- Project Management Office (PMO) consisting of professionals that are experienced in Engineering, Procurement, Fabrication, and Construction Management.

- Personnel include registered Professional Engineers and Project Management Institute (PMI) certified Project Management Professionals (PMP).

- On-Time. On Budget. Exceeding stakeholder expectations.

Process Engineering

- From concept to operation; our team of Process Engineers take an idea from simulation to engineering deliverables to production.

- Using latest Aspentech software (HYSYS) for Process Simulation of oil, gas and renewable energy processes.

- Generation of PFDs, Heat & Material Balance, P&IDs

- Safety studies including hazardous identification (HAZID) and hazardous operation (HAZOP) analysis.

- Operations assistance including commissioning, start-up, and operator training.

- Field troubleshooting assistance and process optimization.

- Lead development of R & D processes to develop client technologies.

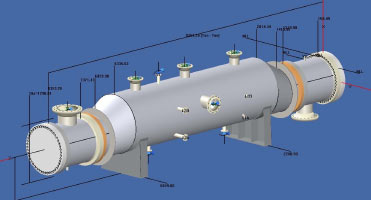

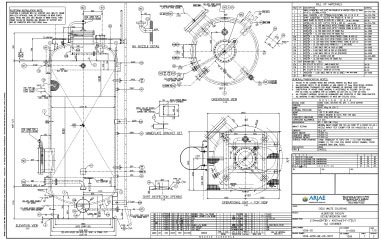

Mechanical Engineering

- Taking a simulated concept, and realizing those ideas into quality fabrication deliverables that meet today’s most stringent codes, standards, and project requirements.

- Pressure Vessel calculations completed using COMPRESS software to the latest ASME Section VIII, Div 1/2/3 requirements. Includes analysis using other internationally recognized standards such as BS5500.

- Heat Exchanger design using latest ASME Section VIII Div1 UHX requirements and TEMA R&C standards.

- Air Cooler design using ASME Section VIII Div1 and API661 design codes and standards.

- Pipe Stress Analysis using CAESARII in compliance with ASME B31.1 and B31.3 requirements. Calculations include static analysis (thermal stress) and dynamic analysis (batch flow or slugging, time-history response, etc.).

Civil and Structural Engineering

- Structural calculations are performed using finite element analysis and Risa 3D software.

- Structural steel calculations are performed to design supporting skids and beams for process equipment and piping, in compliance with today’s most stringent and current codes, standards and specifications including the National Building Code of Canada (NBC), Alberta Building Code (ABC), and international standards such as the International Building Code (IBC).

- All steel design using common shapes and materials to easily source from suppliers including CSA G40.21 300/350W, and ASTM grades.

- Deflection analysis for crane and building installations.

- Foundation analysis for engineered foundations, standard pile loading, concrete pad design and much more.

Instrumentation, Controls and Electrical

- Our instrumentation and automation specialists are experienced in all facets of design which allows them to size and select appropriate instrumentation, ensure it is installed correctly, and calibrate/commissioning correctly.

- Our team is familiar with all major brands of instrumentation and control system hardware and programming platforms to provide adequate service for your new installations and existing equipment.

- Common control system hardware includes Siemens, Allen-Bradley, ABB, Emerson, Yokogawa, and Honeywell.

- ARJAE has in-house electrical specialists that ensure that all switchgear and cable/cable tray is sized adequately and meets all relevant codes, standards, and project requirements.

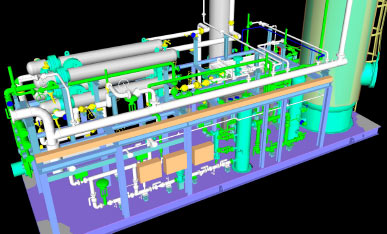

Design Drafting

- Using the latest industry-recognized software, our team of Design Drafters have the ability to take a Process Design and Mechanical calculations, and create a masterpiece.

- ARJAE Design Solutions is an industry leader in modularization design, understanding that in this hyper-competitive global market, the total installed cost (TIC) can be drastically reduced by minimizing field costs while getting your processing equipment running as soon as possible.

- Utilizing AutoCAD and CADWorx, our team of professionals have the ability to generate a model of our equipment, walkthrough with our teams and our clients, ensure operability, and detect model collisions before drawings are released and equipment is built.

- Quality design deliverables are generated based on our approved models. 3D Navisworks models are shared and reviewed with our clients so that they have the opportunity to provide feedback prior to proceeding with fabrication.

- Our 3D models are also reviewed with operations personnel to gain valuable insight and feedback for continuous improvement. We value our client’s opinions and embrace their operations insight to make our design even better.

Document Control and Engineering Support

- Our team of trained professional support staff ensures that our project deliverables comply with in-house standards and projects.

- We utilize cloud-based software to ensure our deliverables are saved in a reliable and safe manner, protecting our assets as well as the confidentiality of our trusted clients.

- Cloud-based access is provided to our clients to access their project deliverables from any web-based platform.

- We also have the ability to work with our clients’ in-house proprietary systems and have experience with commercial software such as Sharepoint, Aconex, and others.

- Our team of Engineering support staff ensures that deliverables are appropriately tracked and approval status from our valued clients is monitored to meet our project requirements while doing so in a cost-effective manner.

Engineering Scope

- Conceptual Design Studies

- FEED Studies

- Basic Engineering Studies

- Research and Development

- Detailed Engineering and Fabrication

- Custom Engineered Package for Client Fabrication

- Custom Parts and Components